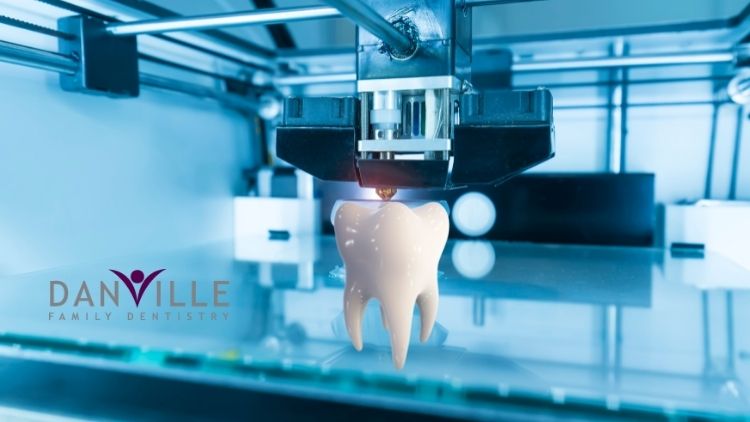

The invention of 3D printers changed some manufacturing, and will probably become more mainstream with every passing day. 3D printing uses an additive manufacturing process. It is the method of printing thin, multi-layers of material to create solid objects. Physical objects are created from digital image files.

This technology is already being used in many industries and now the medical and dental industries have used it as well. Unique human bodies require custom solutions for each patient. 3D printing technology allows this customization to be done and be done with increased efficiency, top quality, and cost effectively.

For some time now, computer-aided design and manufacturing (CAD/CAM) is used in the creation of crowns, veneers, and dental bridges. Using a 3D printer, the outcome is more predictable, less invasive, and much faster. It is ideal for custom dental treatments such as dentures, dental implants, and orthodontic appliances. In addition, digital designs are also reusable, shareable, modifiable, and easy to reproduce with 3D printing.

High levels of customization needed in dentistry have traditionally led to manual methods to create custom materials. 3D printers provide a digital workflow that enables mass customization in an automated way. This process requires less labor and incurs lower cost. In addition, the result is more consistent and reliable, not being dependent on the ability of a given technician to create the pieces manually. Digital technologies simplify workflows, reduce the room for error and the amount of labor required, resulting in time and cost savings on both the lab’s and practice’s side. This cost saving to the dentist is passed down to the patients!

3D Printers and Dentures

Traditional denture manufacturing is a time-consuming and labor-intensive process. That means it involves multiple patient visits and production steps. It is a complex craft with a steep learning curve. Making dentures is both a skill and an art. As a result, dental labs increasingly struggle to find technicians with the advanced skills and expertise required to produce them.

Dentures are one of the latest innovations in digital dentistry. They offer an efficient and cost-effective manufacturing solution. It is a major step toward the overall simplification of the dental laboratory manufacturing process. Denture production with 3D printers includes fewer steps and less variability. Therefore, production is more consistent and results in a higher quality end-product every time.

Dental Implants and technology

3D printing is also used in dental implant procedures. For example, it can produce bone-like complex structures to anchor dental implants, dentures, partials, crowns, or replacement teeth into the jawbone. In addition, digital images are used in placement planning for implants. 3D printing can then produce surgical guides to pinpoint the positioning of the implant. These guides are becoming the new standard of care in implantology. With them, the accuracy of implant placement during surgery is all but guaranteed. Consequently, there is less risk of surgical complications and clinical results are improved overall.

Orthodontics

For orthodontics, a 3D printer can create a model of the teeth to allow the orthodontist to determine the type of misalignment and the best treatment for a reliable diagnosis. Clear aligners are a more and more popular choice for orthodontics and without digital technologies, they would not exist. Impressions of the patient’s teeth are digitally scanned, and the digital model can be manipulated to plan the progressive stages between the current and the desired teeth positions. 3D models of each stage can be printed, and the aligners can then be formed over them.

Patient Experience

Starting with the visit to the dentist or orthodontist, the ability to visualize a dental procedure can be as reassuring for the patient as it is helpful for the practitioner. For instance, a 3D model is helpful in virtual treatment planning, and diagnostic wax-ups. In addition, highly detailed replicas can help patients envision and understand the treatment they will be receiving in detail.

Second, patients experience less anxiety and increased acceptance. Taking an impression of a patient’s teeth with intraoral scanning is quicker and more comfortable than traditional impressions.

The products themselves can be more aesthetically pleasing (clear aligners). In addition, treatments are more accurate and less invasive (digital implantology and surgical guides).

Benefit of Speed

Patient’s visits are quicker and easier because digital elements remove steps. Precise and consistent treatments mean that patients are less likely to need to return for repeat work on the same problem, saving their time and money. Most importantly, a satisfied patient is more likely to become a return customer and refer others. As a result, they are contributing to the long-term success of all dental businesses.

Traditionally, 3D printers used in this process were large and complex to use and prohibitively expensive. Now, smaller format desktop 3D printers are available. That means any lab or practice can have them. With desktop 3D printing the costs are down by a factor of 10-100X. The newest technology in dental 3D printing even involves printers that can print with multiple materials simultaneously. At Danville Family Dentistry we stay abreast of the latest technologies to help you achieve a smile you can be proud of. Contact us today!

Are you on Facebook? We are, too! Let’s be friends!

Disclaimer: The information included in this article is for educational purposes only. It should not be used as a substitute for professional medical advice, diagnosis, or treatment

(317) 745-4400

(317) 745-4400 info@danvilledentalcare.com

info@danvilledentalcare.com